Introduction Preface Section 0: Cybernetic Eyes Section 1: The Quick Guide to the VSM Section 2: Case Studies Hebden Water Milling 1985 Triangle Wholefoods 1986 One Mondragon Co-operative 1991 Section 3: Preliminary Diagnosis Janus interlude Section 4: Designing Autonomy Section 5: The Internal Balance Section 6: Information Systems Section 7: Balance with the Environment Section 8: Policy Systems Section 9: The Whole System Section 10: Application to Federations Bibliography Links Appendix 1: Levels of Recursion Appendix 2: Variety  This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. |

Case Study 3: ONE MONDRAGON CO-OPERATIVE

BACKGROUNDMy visit to Mondragon was primarily to study the way that they manage to get 173 different co-operatives to collaborate. However, the structure of their manufacturing plants has been changing recently, and these changes were of direct relevance to the conclusions I have been coming to through VSM diagnosis. Mondragon are the most successful group of co-operatives that I know, and during the visit I made in February 1991 I was continuously impressed by their commitment to both co-operative ideals and to state-of-the art production techniques. All the factories are full of computer controlled machine tools and robots. They have huge warehouses run entirely by computer. And most of the steel presses and control gear are made by other factories within the Mondragon group. Some general comments are needed before beginning the description of a single Mondragon co-operative.

ORGANISATION OF ONE MONDRAGON CO-OP

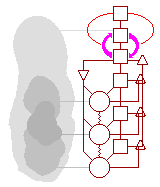

The General Assembly meets once or twice a year, involves all members and is concerned with major policy issues, such as membership rules, production targets, budgets and distribution of profits. Its decisions are binding. The Board of Directors is elected; members are unpaid and serve for 4 years, meeting once a month. They review and co-ordinate operations, appoint the Management who attend meetings but cannot vote. It sets Operational policy. The Management are the executive body of the business, serve for 4 years and have full administrative control. The Audit Group consists of 3 members elected by the General Assembly who inspect the accounts, sometimes calling in experts. They alert managers of problems (which they are expected to resolve), produce information for the General Assembly, and may alert the Co-op of crisis. The Workers Council consists of all members. It meets monthly to discuss matters such as wages, conditions and safety. It represents the work force on the Board of Directors. The Operation covers the basic activities of the system. DIAGNOSISAt the Metasystemic level, all four VSM functions may be clearly identified. System 5: PolicyThe General Assembly deals with the major policy issues and elects the Board to set Operational policy in its monthly meetings. The Board provides the monitoring function whereby the rest of the Metasystem is seen to operate within policy guidelines. System 4: Long Term Planning Long terms plans are drawn up by the Management and sent to the Board for approval. Some debate may follow. System 3: Optimisation This is the responsibility of the Management and seems to be taken seriously. They discuss "synergy" between the Operational elements. The Audit group is System 3*, and is a crucial element of System 3 activities. Its job is to provide the information needed to complete System 3's model after the usual information from the business has been obtained. All companies have some sort of audit function - Mondragon seem to have realised the importance of theirs. System 2: Stability The Mondragon philosophy provides an extremely effective stabilising system. There are further System 2 bodies like production scheduling and cash flow control. But generally everyone seems to work together well, and conflict of interests get resolved easily. System 1: Operation In 1982 the General Assembly decided to change the basic working procedures within the Operation. It was felt that on the shop floor members lacked motivation and that more participation was needed. They reorganised the production lines into autonomous work groups of about 8 people in which everyone could do all the jobs. Instead of working with a time horizon of 45 seconds , each group had to complete its task in 16 minutes. This gave people time to make a phone call, or have a quick cigarette or whatever. In the washing machine factory they changed a 300m line with 70 people into 7 lines 30m long, each with 8 people. The change led to a self-organising system, more motivation, and improved productivity and quality. This system of autonomous Operational elements uses performance indicators. These measure quantity, quality and costs. The daily indicators are measured (e.g. the number produced). Each week they estimate the more subjective measures (e.g. safety, tidiness, autonomy) and give themselves marks out of 10. This number has to be agreed with the foreman who has the final say. Each work group has responsibility for maintenance, quality, design and so on. At monthly meeting they monitor production targets, discuss problems, arrange training and so on. CONCLUSIONSSystem DesignThroughout the description of how the Mondragon co-operatives function I found it hard to believe that the system had not been based upon the VSM. In the five years since the Doughnut proposals at Suma I have been attempting to introduce performance indicators, long term planning functions and the like, and almost everything I have been proposing is standard procedure at Mondragon. Perhaps the only aspect that could be improved is the statistical analysis of the daily information to generate Algedonics automatically. As far as I can tell, they inspect all the information they generate. Participation in PolicyIt has always seemed fundamental that all members of a co-operative have the ability to affect policy at all levels and Mondragon seem to adhere to this principle. Within the co-operative all members make policy at yearly meetings, and occasionally at emergency General Assemblies called by a minimum of 10% of the co-op. During my visit to the Refrigerator factory there were notice boards everywhere full of information on the policy issues which were to be debated at the next General Assembly. Representative ManagementThey give their elected managers "full administrative authority" although they insist that this can only be maintained if the manager has the trust of the workforce. (He can be removed by an emergency General Assembly.) It's clear that some Metasystemic functions must be performed without continuous consultation with the work-force (for example long term plans) and at Mondragon they seem to have found a balance between complete authoritarian control and the lack of clear decision making that comes from having to discuss everything with everyone. The model which was offered to us was that of a busload of people who instruct the driver as to where they want to go, and then leave the details to him. Once he's been instructed, the rest of the people on the bus leave him to operate the brakes, steer and accelerate as he sees fit. The passengers can also direct him to drive more safely, or get another driver if he's no good. But basically it's up to him to drive the bus. Finally .. The Mondragon structure seemed to me to be an example of both efficiency and co-operation based firmly upon autonomy and participation. The VSM diagnosis revealed no major flaws, even in the details of how Operational information is gathered. |

|||||